Table of Contents

Have you ever wondered how diesel engines work? They may seem complex, but fear not! In this step-by-step guide, we will unravel the mysteries surrounding diesel engines and shed light on their inner workings. So, buckle up and prepare to embark on an exciting journey of discovery!

At its core, a diesel engine is a marvel of engineering that converts the chemical energy in diesel fuel into mechanical power. Unlike gasoline engines, which rely on spark plugs for ignition, diesel engines use compression to ignite the fuel. This unique characteristic makes diesel engines highly efficient and reliable.

Let’s dive into the first step of our guide: the intake stroke. During this stage, the engine draws air into the combustion chamber. As the piston moves downward, it creates a vacuum, allowing fresh air to enter. This influx of air is essential for the combustion process.

Next comes compression. As the piston moves back up, it compresses the air within the cylinder. The compression ratio in a diesel engine is much higher than in a gasoline engine, leading to increased efficiency. This heightened compression causes the air temperature to rise significantly.

Now, it’s time for fuel injection. Precisely timed and pressurized, the fuel is injected into the combustion chamber. When the fuel mixes with the hot compressed air, ignition occurs spontaneously due to the high temperatures. This ignition creates a controlled explosion, pushing the piston back down.

The final step is exhaust. After the power stroke, the piston moves upward, expelling the burned gases through the exhaust valve. This process sets the stage for the next cycle, and the engine continues running as long as fuel is supplied.

To summarize, diesel engines operate through four main steps: intake, compression, combustion, and exhaust. Understanding these steps brings clarity to the fascinating world of diesel engines. Their robust design and efficiency make them ideal for various applications, from powering heavy machinery to propelling large vehicles.

diesel engines are a testament to human ingenuity and engineering prowess. By demystifying their inner workings step by step, we hope you now have a clearer understanding of how these remarkable machines operate. Embrace the wonder of diesel engines and appreciate the power they deliver!

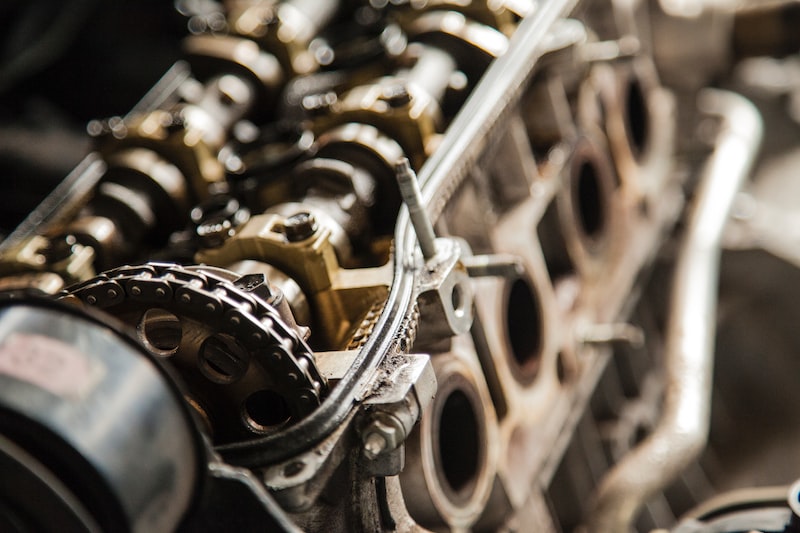

Unlocking the Engine’s Secrets: A Comprehensive Visual Journey Through Diesel Engines

Are you ready to embark on

a captivating visual journey through the marvels of diesel engines? Buckle up as we dive into the world of these powerful machines, uncovering their secrets and demystifying the inner workings that make them tick. Get ready for an exhilarating ride!Diesel engines have long been the workhorses of various industries, renowned for their efficiency and raw power. But what lies beneath their rugged exterior? Let’s take a closer look.

At the heart of every diesel engine is a combustion process that utilizes compression ignition. Unlike gasoline engines that rely on spark plugs, diesel engines compress air within the cylinders until it reaches high temperatures. This heat ignites the fuel injected into the combustion chamber, setting off a controlled explosion that propels the engine forward.

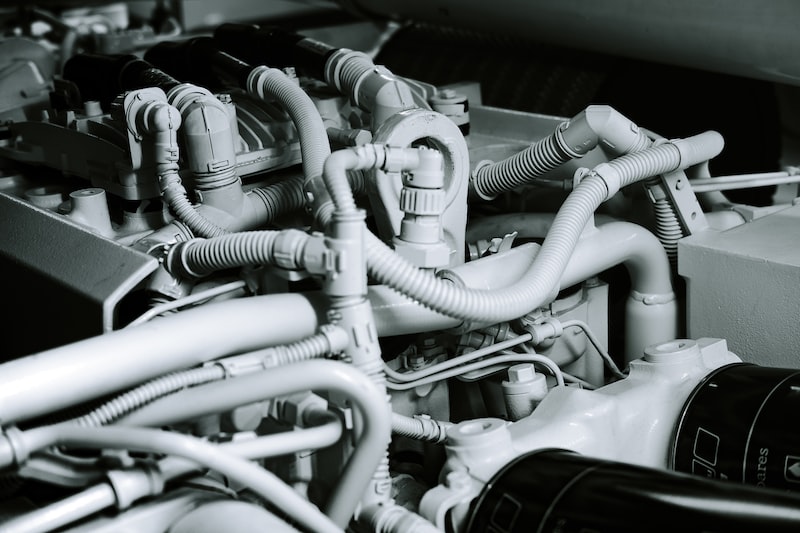

One key element in this process is the fuel injection system. Think of it as the engine’s very own fuel distribution network. This system precisely delivers fuel to each cylinder at the right moment, ensuring optimal combustion and maximum power output. It’s like a synchronized dance, with each injector playing its part to perfection.

But what about the engine’s breathing apparatus? That’s where the air intake system comes into play. Just as we need to breathe clean air, diesel engines require a steady flow of fresh air for optimal performance. Air filters prevent harmful contaminants from reaching the cylinders, protecting vital components and ensuring the engine’s longevity.

Now, let’s shift our focus to the engine’s powerhouse – the turbocharger. Picture a mini jet engine nestled within the diesel engine, harnessing waste exhaust gases to compress incoming air. By doing so, the turbocharger significantly boosts the engine’s power output, akin to an athlete inhaling pure oxygen before a race.

To keep all these moving parts working harmoniously, diesel engines rely on various fluids. Lubricating oil ensures smooth operation of the engine’s components, reducing friction and minimizing wear. Coolant regulates temperature, preventing overheating that could damage vital parts.

diesel engines are a symphony of mechanical prowess, where precision and power coexist. From the fuel injection system to the air intake and turbocharging, every component plays a vital role in unlocking the engine’s secrets. Now that you’ve had a glimpse into their inner workings, prepare to be amazed by these mechanical marvels on your next encounter with a diesel-powered vehicle or machinery.

From Pistons to Exhaust: Demystifying Diesel Engines in 10 Easy Steps

Are you ready for a thrilling ride into the world of diesel engines? Buckle up and hold on tight as we demystify these powerful beasts in 10 easy steps. From the pistons that ignite the fuel to the roaring exhaust, we’ll break it down for you in a language anyone can understand.

Step 1: Fuel Injection

Diesel engines rely on fuel injection systems to deliver precise amounts of diesel fuel into the combustion chamber. Unlike gasoline engines, which use spark plugs to ignite the fuel-air mixture, diesel engines compress the air and inject fuel directly into the hot, compressed air.

Step 2: Compression Ignition

The magic happens when the piston compresses the air inside the combustion chamber. The high compression heats the air to such an extent that it ignites the injected diesel fuel without the need for a spark. This is known as compression ignition, the defining characteristic of diesel engines.

Step 3: Turbocharging

Turbochargers are like the lungs of a diesel engine. They force more air into the combustion chamber, allowing more fuel to burn and generating greater power output. Think of it as giving your engine a shot of adrenaline!

Step 4: Glow Plugs

During cold starts, diesel engines employ glow plugs to heat up the combustion chambers. These little helpers ensure that the air inside the engine reaches the required temperature for efficient ignition, even in chilly weather.

Step 5: Four-Stroke Cycle

Similar to gasoline engines, diesel engines operate using a four-stroke cycle: intake, compression, power, and exhaust. However, the key difference lies in the combustion process, as explained earlier.

Step 6: Combustion Efficiency

Diesel engines are renowned for their high combustion efficiency. This means they extract more energy from each drop of fuel compared to gasoline engines. That’s why diesel engines are commonly used in heavy-duty applications like trucks and industrial machinery.

Step 7: Torque

Diesel engines are torque monsters! Torque refers to the twisting force that generates power and enables heavy pulling or towing capabilities. Diesel engines excel in delivering massive amounts of torque, making them ideal for hauling heavy loads.

Step 8: Durability

Diesel engines are built tough to withstand the rigors of demanding work conditions. Their robust design and lower operating temperatures contribute to their reputation for longevity and reliability.

Step 9: Fuel Efficiency

Efficiency is the name of the game when it comes to diesel engines. Thanks to their high compression ratios and efficient combustion process, diesel engines offer superior fuel efficiency compared to gasoline engines.

Step 10: Environmental Impact

While diesel engines have traditionally been associated with higher emissions, advancements in technology have led to cleaner diesel engines. Modern diesel engines employ sophisticated emissions control systems to reduce pollutants and meet stringent environmental regulations.

And there you have it — a whirlwind tour through the inner workings of diesel engines. From fuel injection to the exhaust, we’ve peeled back the layers and demystified these incredible powerhouses. So, next time you hear the rumble of a diesel engine, you’ll know exactly what’s going on under the hood.

Power and Performance Unveiled: Exploring the Inner Workings of Diesel Engines

Are you ready to embark on a thrilling journey into the realm of diesel engines? Today, we uncover the hidden secrets behind their power and performance. Buckle up and get ready to delve into the inner workings of these mechanical marvels.

Have you ever wondered what makes diesel engines tick? Unlike their gasoline counterparts, diesel engines operate on a different principle. Instead of using spark plugs to ignite the fuel-air mixture, they rely on high compression to generate the necessary heat for combustion. This compression-ignition process is what sets them apart and gives them their incredible power.

Picture this: as the piston moves upwards within the cylinder, it compresses the air trapped inside. This compression causes the air temperature to rise dramatically. When the piston reaches the top of its stroke, fuel is injected directly into the superheated air. The moment the fuel comes into contact with the hot air, it ignites spontaneously, creating an explosion that drives the piston downwards with immense force. This raw power is harnessed and converted into rotational motion, which propels the vehicle forward.

But wait, there’s more! Diesel engines are renowned for their exceptional torque output. Torque, simply put, is the twisting force that rotates the engine’s crankshaft. Due to their robust construction and higher compression ratios, diesel engines produce more torque than their gasoline counterparts. This extra torque translates into superior pulling power, making diesel engines ideal for heavy-duty applications such as towing and hauling.

Moreover, diesel engines are known for their longevity and fuel efficiency. With proper maintenance, these powerhouses can clock hundreds of thousands of miles without breaking a sweat. Thanks to their efficient combustion process, diesel engines extract more energy from each drop of fuel, resulting in better fuel economy compared to gasoline engines.

diesel engines exhibit a unique blend of power, performance, and durability. Their ingenious compression-ignition system, coupled with exceptional torque output and fuel efficiency, sets them apart from the crowd. Whether it’s hauling heavy loads or cruising down the highway, diesel engines continue to be a force to be reckoned with in the world of automotive engineering. So next time you see a diesel-powered vehicle, take a moment to appreciate the remarkable inner workings that make it all possible.

Diesel Engines Decoded: A Captivating Illustrated Guide for Beginners

Are you ready to embark on a captivating journey into the world of diesel engines? In this illustrated guide, we will unravel the mysteries surrounding these powerful machines. Whether you’re a curious beginner or simply fascinated by the inner workings of these beasts, this article will provide you with an engaging overview of diesel engines.

So, what exactly is a diesel engine? Unlike its gasoline counterpart, a diesel engine relies on compression ignition rather than a spark to ignite the fuel-air mixture. This unique characteristic gives diesel engines their distinct sound and power. Imagine a synchronized dance between the air and fuel, orchestrated by the engine’s mechanical components, resulting in controlled explosions that propel vehicles and machinery forward. It’s like the beating heart of a mechanical beast!

One of the key advantages of diesel engines lies in their efficiency. Due to the high compression ratios they achieve, diesel engines extract more energy from each drop of fuel. This leads to greater fuel economy, making them popular choices for heavy-duty applications such as trucks, locomotives, and ships. Not to mention, diesel engines are known for their torque, providing impressive pulling power for towing and hauling.

Now, let’s take a closer look at the inner workings of a diesel engine. Picture a series of precisely timed events that occur within its cylinders. As the piston moves downwards during the intake stroke, air is drawn in, compressed, and heated. Next comes the magic moment: fuel injection. The fuel is injected into the combustion chamber at just the right time, igniting under the high pressure and generating force that pushes the piston back down. This process repeats with each cylinder firing in sequence, creating a continuous rotation of the crankshaft that powers the vehicle.

Diesel engines are also known for their longevity and durability. The sturdy design and robust construction enable them to withstand high compression forces and heavy workloads. With proper maintenance and care, diesel engines can serve faithfully for hundreds of thousands of miles.

diesel engines offer a captivating blend of power, efficiency, and reliability. Their unique combustion process sets them apart from their gasoline counterparts, providing superior torque and fuel economy. Whether you’re considering purchasing a diesel-powered vehicle or simply curious about the inner workings of these mechanical marvels, this illustrated guide has provided you with a glimpse into the world of diesel engines. Embrace the fascination, and let the journey continue!